Call : 08045801299

Bulkhead Lock Nut

350 INR/Piece

Product Details:

- Color Silver

- Product Type Bulkhead Lock Nut

- Material Stainless Steel

- Surface Galvanized

- Click to View more

X

Bulkhead Lock Nut Price And Quantity

- 350 INR/Piece

- 10 Piece

Bulkhead Lock Nut Product Specifications

- Galvanized

- Stainless Steel

- Bulkhead Lock Nut

- Silver

Bulkhead Lock Nut Trade Information

- Telegraphic Transfer (T/T) Cheque

- 50 Piece Per Day

- 2-3 Days

- Australia North America Eastern Europe Central America Middle East South America Western Europe Asia Africa

- All India

Product Description

Product Details:| Material Procurement | Supplier End |

| Location Type | Industrial |

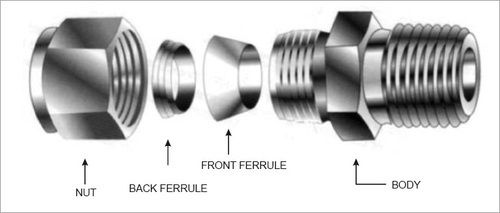

| Although the fittings consist of four components: Nut, back ferrule, front ferrule and the body, it becomes a four piece connection when affixed to tubing. The two ferrule design and sequential action of the fittings overcome in-variation of tube wall thickness and hardness to assure safe, reliable, leak-free connections PMT tube fittings are easily installed without any special tools. The front ferrule swages onto the tube as it moves down the cone of the body creating a pressure/vacuum tight seal on both tube and body by interface pressure and surface finish of matching components. The back ferrule, deforms into the tube creating a strong mechanical and anti-vibration hold on the tube. The internal diameter of body and nut are closely controlled which constrain the tube within a close tolerance of its axis ensuring accurate alignment within the assembled fitting. In case of S.S. tube fittings high hardness of ferrules of ferrules is assured / maintained (more than Rd 90 ) For reliable joints the positive tolerances on inside diameter of ferrules and body is kept to minimum. The nut threads are silver coated to ensure no galling |

| Thus the design features on the tube end side can be summarised as below. 1) The back ferrule dampens the tube circuit vibration through a spring like action. Further more, it prevents a carry over of tightening torque from the fitting nut to front ferrule 2) The front ferrule circumferentially seals the surface between the tube and fitting. The inner taper of front ferrule is pressed on the tube so that a pressure tight impression is formed. 3) Silvering of nut threads prevents seizing/galling. This allows repeated use of fittings. 4) A deep body bore on tube side and taper, guarantees accurate positioning and centering of tube. The twin ferrule connection does not in any way reduce the strength of the tube and therefore tube having thin wall PMT twin ferrule connection does not in any way reduce the strength of the tube and therefore tube having thin wallcan be used without affecting the safety of installation. |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry